Tube round conification

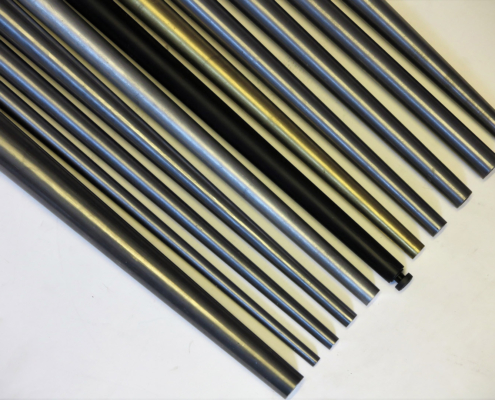

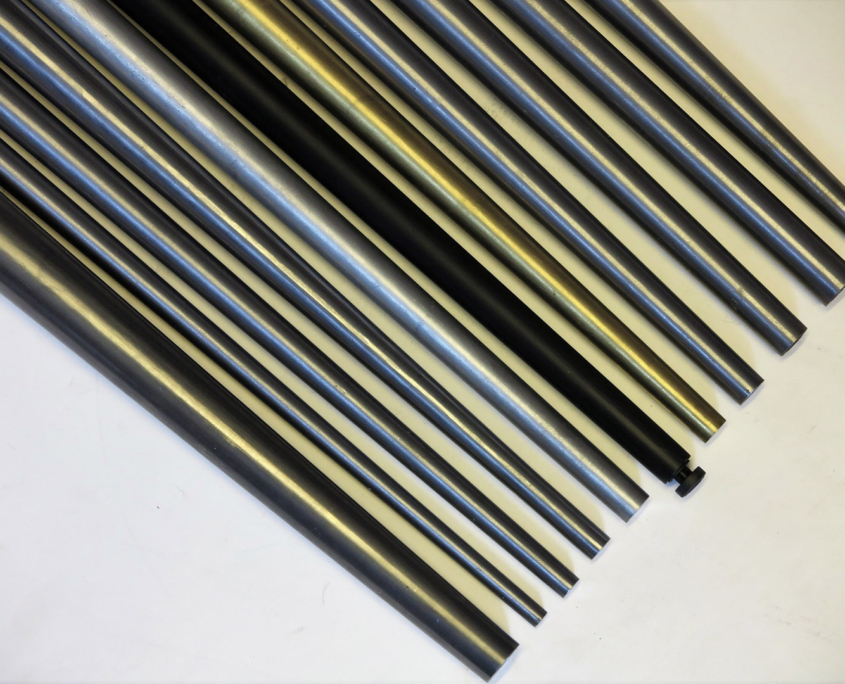

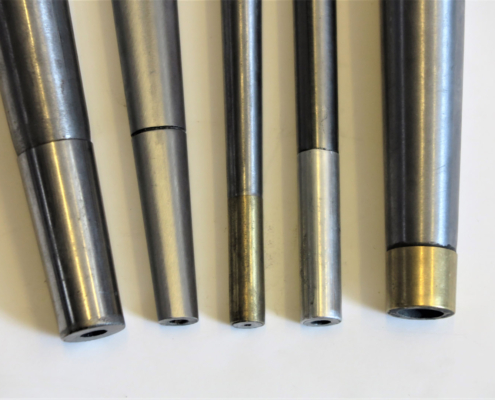

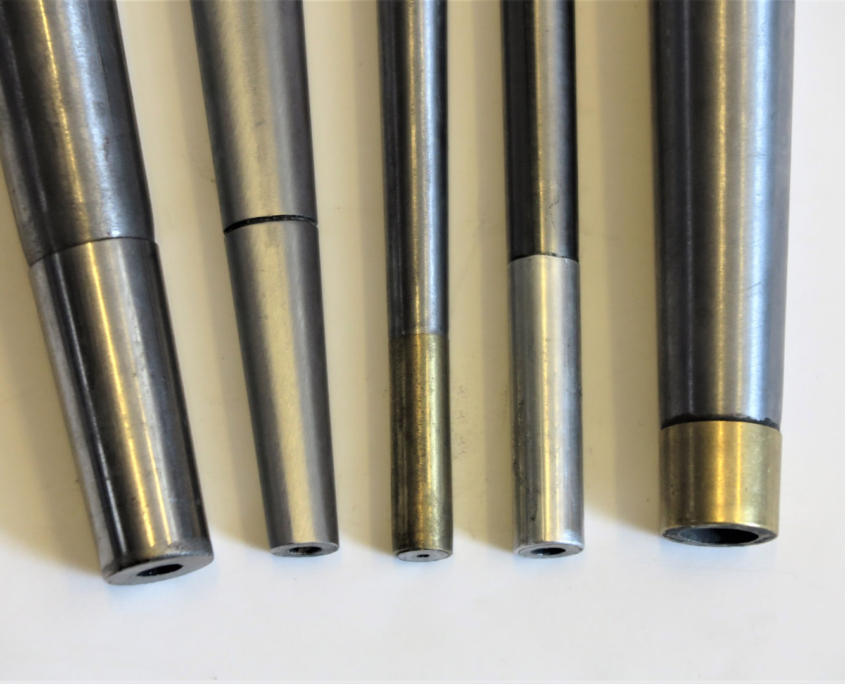

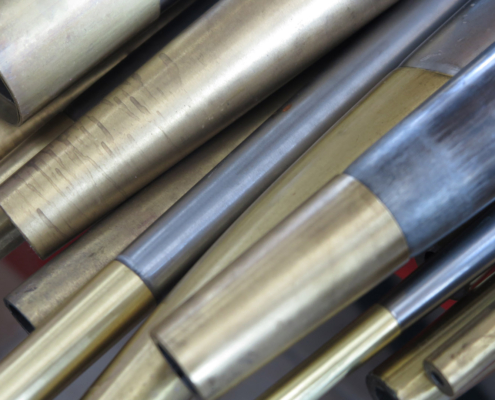

Making a round tube conification means reducing the cylindrical metal tubes from a larger diameter to a smaller diameter, to a conical shape and in the desired length, thus obtaining conical metal tubes for conification.

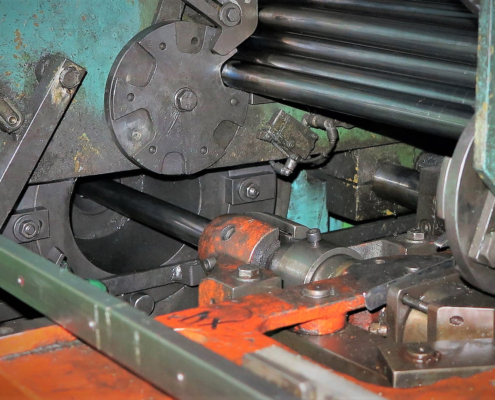

GAMMA 3 obtains this pipe and tube conification process by means of cold mechanical hammering, with the use of various machines and special dedicated tube conification moulds.

Keep reading

It is called round tube conification, due to the section of the pipe, in this case round or circular.

However, it is possible to obtain a tube conification starting from a tube with a different section (square, rectangular, elliptical, oval), and to obtain conical metal tubes starting from the different section, and ending with the round conical section.

Conversely, it is possible to start from a tube with a round section, and make a conification of tubes with a square, rectangular, triangular, oval section, to obtain conical metal tubes with a larger diameter with a cylindrical section, and a smaller diameter with a different section.

These conical metal tubes obtained by round tube conification are the main processing of GAMMA 3, and with this processing it is possible to process up to 80 mm in diameter and up to 5 meters in length of the conical part.

The fleet of machines and molds for tube conification is really very large, in order to satisfy the greatest possible number of requests.

We make custom-made tapered tubes, and we can also design and have custom molds produced.

Conical metal tubes of this kind are used in various sectors, such as home and office furnishings, street furniture, fences, lighting, chandeliers, automotive, machinery, construction, plumbing, nautical.

GAMMA 3 designs and manufactures round conical metal tubes with a maximum diameter of 80 mm and a length of up to 5 meters in the following materials: iron, brass, aluminium, stainless steel, titanium, copper, silver.

It is also possible to make tube conification on both tube’s sides, very common in chairs and fences.

The tube conification processes take place both with automatic and manual procedures, with the selection of the best raw materials.

Our automated systems, for the entire production chain, guarantee competitive prices on production lots.

We also produce small series and samples of tube conification and all our other processes.

This carefully managed production system allows us to obtain unique and superior quality conical metal tubes.

Our vast rangch major diameter, minor diameter and length.

Tube round conification

Making a round tube conification means reducing the cylindrical metal tubes from a larger diameter to a smaller diameter, to a conical shape and in the desired length, thus obtaining conical metal tubes for conification.

GAMMA 3 obtains this pipe and tube conification process by means of cold mechanical hammering, with the use of various machines and special dedicated tube conification moulds.

It is called round tube conification, due to the section of the pipe, in this case round or circular.

However, it is possible to obtain a tube conification starting from a tube with a different section (square, rectangular, elliptical, oval), and to obtain conical metal tubes starting from the different section, and ending with the round conical section.

Keep reading

Conversely, it is possible to start from a tube with a round section, and make a conification of tubes with a square, rectangular, triangular, oval section, to obtain conical metal tubes with a larger diameter with a cylindrical section, and a smaller diameter with a different section.

These conical metal tubes obtained by round tube conification are the main processing of GAMMA 3, and with this processing it is possible to process up to 80 mm in diameter and up to 5 meters in length of the conical part.

The fleet of machines and molds for tube conification is really very large, in order to satisfy the greatest possible number of requests.

We make custom-made tapered tubes, and we can also design and have custom molds produced.

Conical metal tubes of this kind are used in various sectors, such as home and office furnishings, street furniture, fences, lighting, chandeliers, automotive, machinery, construction, plumbing, nautical.

GAMMA 3 designs and manufactures round conical metal tubes with a maximum diameter of 80 mm and a length of up to 5 meters in the following materials: iron, brass, aluminium, stainless steel, titanium, copper, silver.

It is also possible to make tube conification on both tube’s sides, very common in chairs and fences.

The tube conification processes take place both with automatic and manual procedures, with the selection of the best raw materials.

Our automated systems, for the entire production chain, guarantee competitive prices on production lots.

We also produce small series and samples of tube conification and all our other processes.

This carefully managed production system allows us to obtain unique and superior quality conical metal tubes.

Our vast rangch major diameter, minor diameter and length.