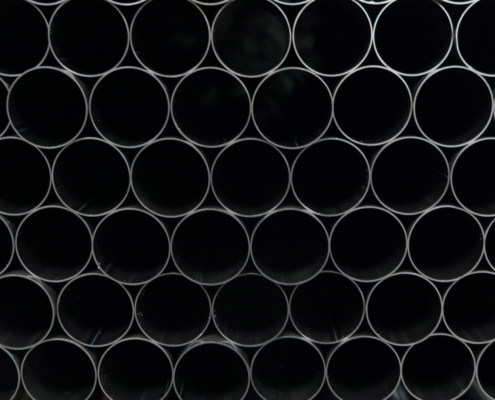

Automatic tube cutting to length

Cutting tubes and pipes to length for large quantities is a fundamental aspect for the success of the job, due to the importance of having a precise, clean, and above all fast cut of metal tubes.

GAMMA 3 is placed on the automatic tube cutting market for third parties and for internal production with a considerable production capacity of its own machines, such as cutters and an automatic cutting line, specially designed for high-performance metal tube cutting.

Keep reading

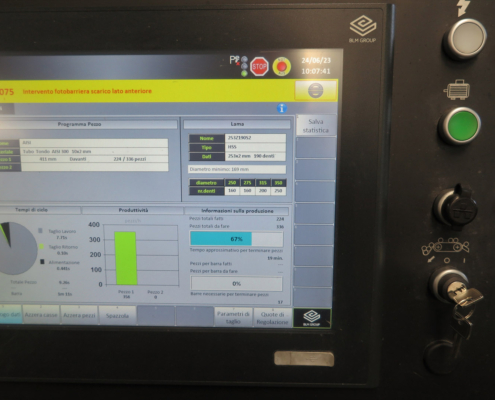

Our tube cutting to length includes these phases: choice and selection of the material suitable for subsequent processing, loading into an automatic cutting line managed by modern industry 4.0 systems, automatic tube cutting to length, automatic brushing (or deburring) on both sides, automatic blowing internal, unloading in the collector, packing.

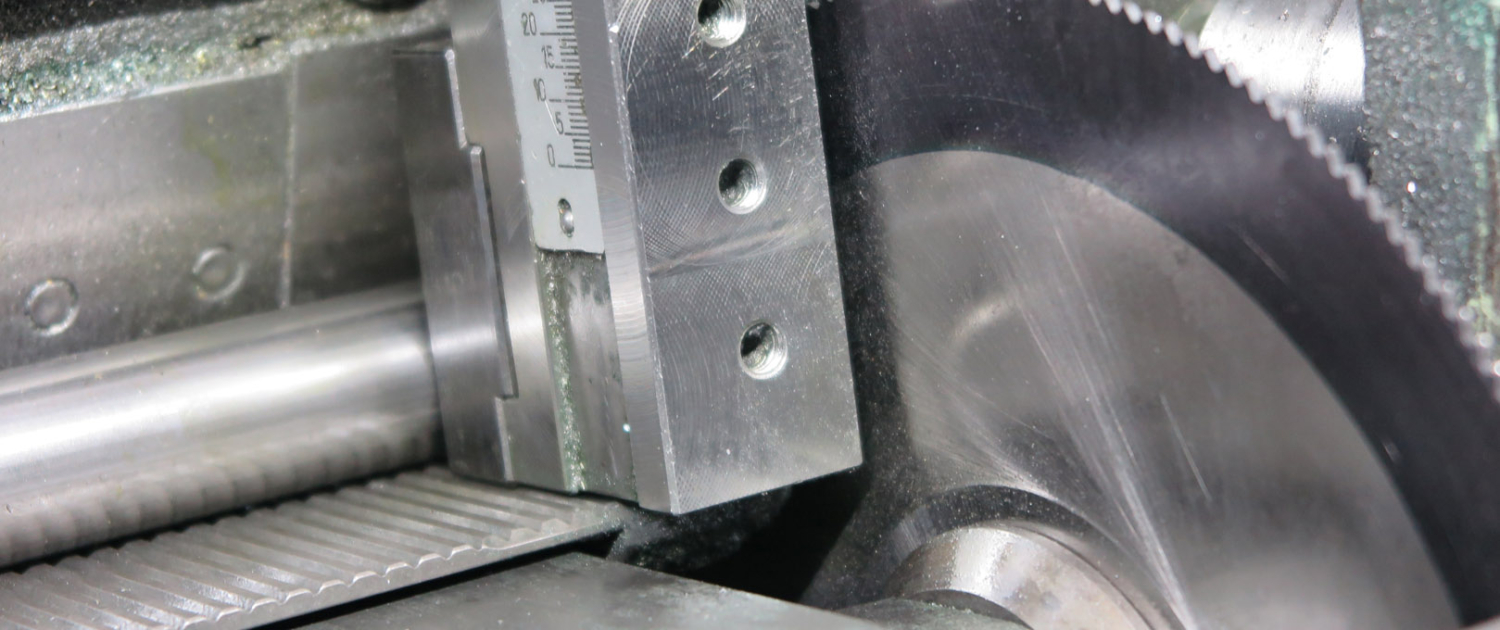

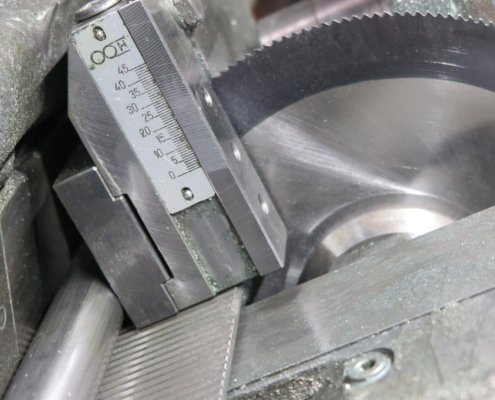

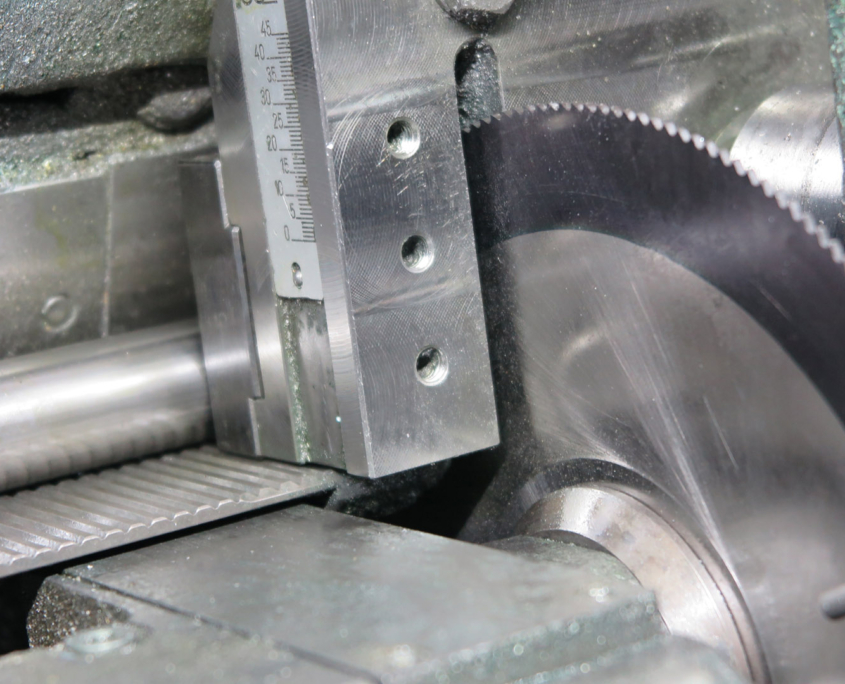

To make an excellent cut of metal tubes and pipes to size, the choice of blades and the right teeth is essential, in relation to the rotation speed and advancement of the blade itself.

The right lubrication also plays a fundamental role in automatic tube cutting to length, guaranteeing longevity of the blade, increased performance, reduction of processing times, and good cleaning of the cut tube as there is no need to use water-emulsifiable lubricants. Our lubrication for cutting metal tubes and pipes is in fact sprayed directly onto the blade, and does not cause dust and burrs to stick to the pipes.

The possible processing materials for our automatic tube cutting to length are iron, brass, aluminum, stainless steel, titanium, copper and silver.

We can automatically manage tubes, pieps, profiles

and bars with a maximum length of 6.50 meters, with a maximum diameter of 80mm, round, square, rectangular, oval, and with a length tolerance of 0.1mm, for tube cutting at precise fit, clean, and uncompromising.

With these metal tubes cutting machines we can also handle softer or thinner materials, thanks to our enveloping and shaped vises on the various round diameters possible for cutting tubes and pipes to size.

We are also available to receive subcontracted material supplies from our customers to cut it.

Automatic tube cutting to length

Cutting tubes and pipes to length for large quantities is a fundamental aspect for the success of the job, due to the importance of having a precise, clean, and above all fast cut of metal tubes.

GAMMA 3 is placed on the automatic tube cutting market for third parties and for internal production with a considerable production capacity of its own machines, such as cutters and an automatic cutting line, specially designed for high-performance metal tube cutting.

Our tube cutting to length includes these phases: choice and selection of the material suitable for subsequent processing, loading into an automatic cutting line managed by modern industry 4.0 systems, automatic tube cutting to length, automatic brushing (or deburring) on both sides, automatic blowing internal, unloading in the collector, packing.

To make an excellent cut of metal tubes and pipes to size, the choice of blades and the right teeth is essential, in relation to the rotation speed and advancement of the blade itself.

The right lubrication also plays a fundamental role in automatic tube cutting to length, guaranteeing longevity of the blade, increased performance, reduction of processing times, and good cleaning of the cut tube as there is no need to use water-emulsifiable lubricants. Our lubrication for cutting metal tubes and pipes is in fact sprayed directly onto the blade, and does not cause dust and burrs to stick to the pipes.

Keep reading

The possible processing materials for our automatic tube cutting to length are iron, brass, aluminum, stainless steel, titanium, copper and silver.

We can automatically manage tubes, pieps, profiles

and bars with a maximum length of 6.50 meters, with a maximum diameter of 80mm, round, square, rectangular, oval, and with a length tolerance of 0.1mm, for tube cutting at precise fit, clean, and uncompromising.

With these metal tubes cutting machines we can also handle softer or thinner materials, thanks to our enveloping and shaped vises on the various round diameters possible for cutting tubes and pipes to size.

We are also available to receive subcontracted material supplies from our customers to cut it.