Tube end closing

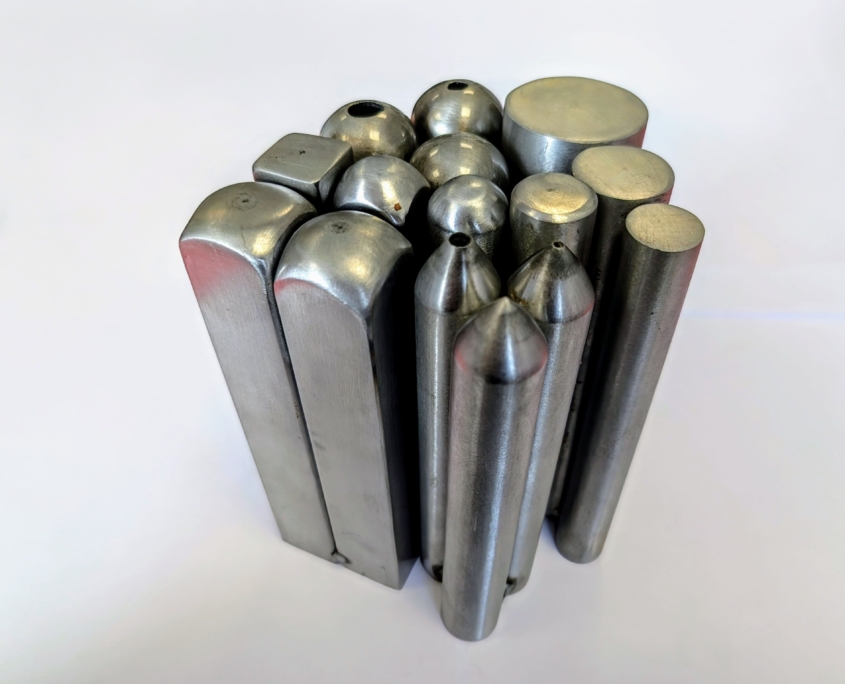

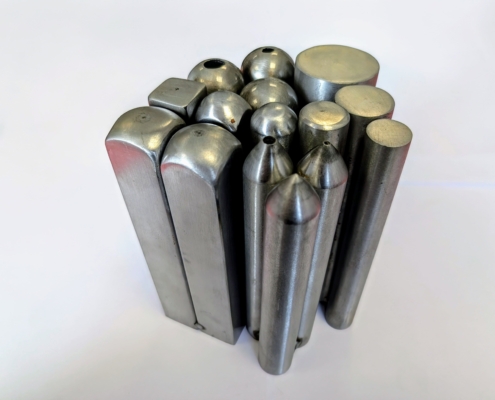

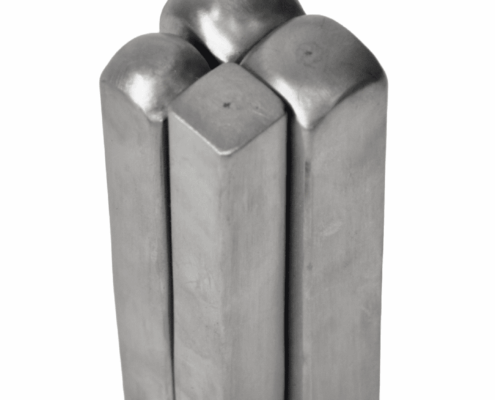

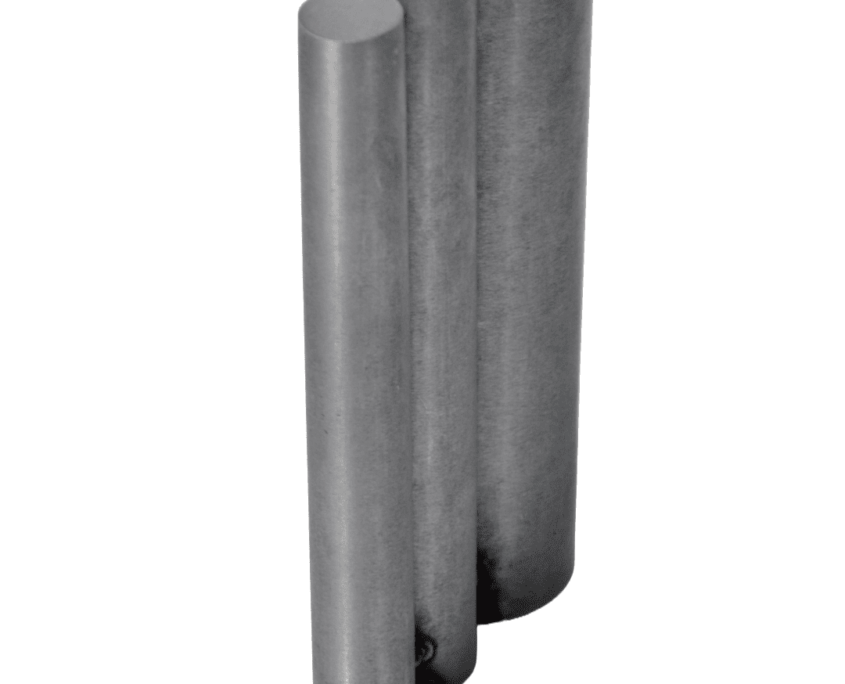

The metal tube end closing allows us to create closed end tubes and pipes, and it is a particular process that is done to obtain a spherical closure at the end of the tube itself.

GAMMA 3 offers the tube end closing as an alternative to more traditional systems, such as welding a cap created by turning, thus creating closed end tubes in a single piece.

In fact, tube end closing is obtained with special and dedicated machines, which work through a cold rolling of the tubes, creating functional and aesthetically beautiful closed end tubes.

Keep reading

Doing a tube end closing without heating means doing a faster, cleaner process, without welding and without oxides or excess welding to grind.

All these advantages that the closed end tubes have, guarantee the product a lower cost than traditional systems, and a more satisfactory result.

During the tube rolling process, the tube is closed at the end, or alternatively semi-closed gradually until it forms a hemisphere.

Furthermore, it is also possible to do tube end closing partially, leaving a hole in the center of the radiused end of the pipe, which can be drilled to the desired diameter, in order to insert, for example a rubber stopper.

GAMMA 3 also offers another type of closed end tubes, made with heating.

The difference between this process and the previous one lies in the fact that a cold-sealed tube has micro-fractures (absolutely invisible in case of painting, chroming or any other galvanic treatment), while a hot-sealed tube has the same aesthetics, but it also has a watertight seal.

The need for watertightness in tubes and pipes closures is required by the radiator and plumbing industry in general.

Alternatively, it is possible to create closed end tubes without heating, which are then closed in a watertight manner by soldering or welding.

GAMMA 3 can do tube end closing for metal pipes with various diameters and with various types of metal.

The most frequent use of this process is for fences, handrails and parapets, the construction sector, urban furniture, the plumbing sector, the furniture and office furniture sector, furniture and sofa feet, chair and stool legs.

Tube end closing

The metal tube end closing allows us to create closed end tubes and pipes, and it is a particular process that is done to obtain a spherical closure at the end of the tube itself.

GAMMA 3 offers the tube end closing as an alternative to more traditional systems, such as welding a cap created by turning, thus creating closed end tubes in a single piece.

In fact, tube end closing is obtained with special and dedicated machines, which work through a cold rolling of the tubes, creating functional and aesthetically beautiful closed end tubes.

Doing a tube end closing without heating means doing a faster, cleaner process, without welding and without oxides or excess welding to grind.

All these advantages that the closed end tubes have, guarantee the product a lower cost than traditional systems, and a more satisfactory result.

During the tube rolling process, the tube is closed at the end, or alternatively semi-closed gradually until it forms a hemisphere.

Keep reading

Furthermore, it is also possible to do tube end closing partially, leaving a hole in the center of the radiused end of the pipe, which can be drilled to the desired diameter, in order to insert, for example a rubber stopper.

GAMMA 3 also offers another type of closed end tubes, made with heating.

The difference between this process and the previous one lies in the fact that a cold-sealed tube has micro-fractures (absolutely invisible in case of painting, chroming or any other galvanic treatment), while a hot-sealed tube has the same aesthetics, but it also has a watertight seal.

The need for watertightness in tubes and pipes closures is required by the radiator and plumbing industry in general.

Alternatively, it is possible to create closed end tubes without heating, which are then closed in a watertight manner by soldering or welding.

GAMMA 3 can do tube end closing for metal pipes with various diameters and with various types of metal.

The most frequent use of this process is for fences, handrails and parapets, the construction sector, urban furniture, the plumbing sector, the furniture and office furniture sector, furniture and sofa feet, chair and stool legs.